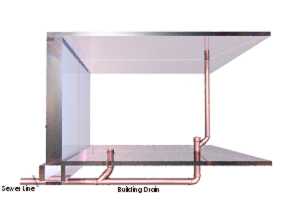

An Auger Machine is used to resolve drainage problems in sewer and drain lines.

Because most stoppages are caused by solids accumulating within the line, the Auger Machine has proved to be the most sensible approach.

The machine uses a cable housed within a drum. Usually controlled with a foot pedal, the drum spins when the motor is engaged. As the drum turns, the cable is fed into the drain or sewer. When the cable end is fitted with the correct attachment, the drain or sewer can be cleaned as sewage, mineral, fat and other accumulations are alleviated.

Note : Although, with augering, most drainage problems are resolved, there may be cases where other remedies may be necessary.

Kitchen sink drains may require water jetting. However, failure to auger the drain first could lead to back wash situations. More specifically, should a hard blockage exist, water from the water jet is likely to back up into the drain of approach or other connected drains.

If kitchen sink stoppages are fairly common in your household or place of business, water jetting may provide a long term solution and result in better value.

Should the sewer or drain be defective (collapsed, perforated, separated, etc.), augering the line can produce a temporary solution at best and other remedies will be necessary.